What should focus on in thermal defect detection?

In industry, the provision of reliable power is critical to equipment safety and personnel safety, and it ensures the smooth operation of motors, transformers, conductors, power cables, and other types of electrical installations.

There are often a large number of switches, contacts, wiring, casing clamps and other components in the electrical equipment system, which cause abnormal overheating points due to poor contact, corrosion, internal abnormalities and other reasons, jeopardizing the normal operation of the equipment as well as the safety of the power supply, and leading to electrical fires in serious cases.

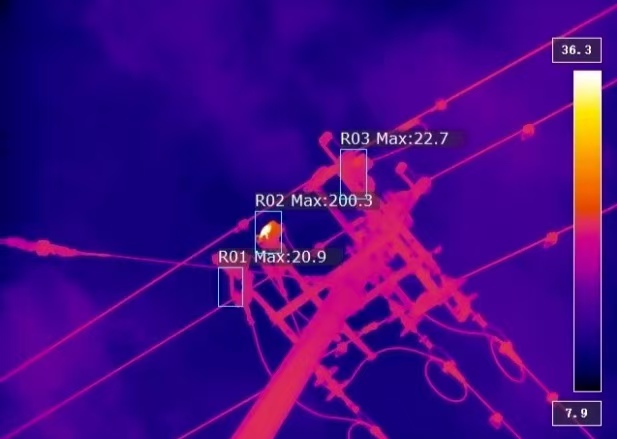

Infrared thermal imaging is a fast and efficient means of detection, can accurately detect the over-hot spot, timely elimination of hidden dangers, to ensure the safety of power supply, and at the same time effectively reduce the maintenance costs, to ensure the safety of power supply.

So how are thermal defects formed? Thermal defect detection and what to focus on?

According to the different reasons for defects, we usually summarize the following categories:

-Components exposed to air for a long time, due to temperature, humidity, surface scaling and other effects caused by poor contact.

-Due to external forces caused by damage to the components, so that the conductive cross-sectional area of the heat generated by the reduction. Such as poor connection joints, bolts, washers are not pressed or over-tightened.

-Long-term operation of corrosion and oxidation; the atmosphere of the active gas, dust caused by corrosion; components of poor material, processing and installation technology is not good conductor damage; mechanical vibration and other reasons caused by the actual cross-section of the conductor is reduced.

-Load current is not stable or exceed the standard, etc.

-Due to the internal failure of the equipment itself, such as poor contact of the internal connection parts resulting in excessive resistance.

The detection of thermal defects needs to be emphasized:

-Outlet joints, internal conductive circuit connection detection

-Various types of conductive connectors, wiring connectors oxidation corrosion, poor connection defect detection

-Detection of heat generation in wire clips